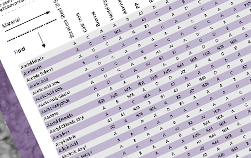

Our Fluid Compatibility Guide

When choosing the right pump for your requirements, carrying out a fluid compatibility check should be at or near the top of your to do list. Certain fluid/material combinations can result in corrosion, swelling, brittleness, leaking and even dissolving of the pump.

To avoid a bad fluid/material combination, which can be costly, troublesome and cause you downtime, we have put together ourguide to fluid compatibility. This guide shows a comprehensive list of fluids and how they react with the materials that pumps are commonly constructed of, to help you select the best material for your fluid.

Certain pump designs are also better suited to certain fluids. The working principle of of each pump type determines its ability to handle certain viscosities, chemical properties, temperatures, shear sensitivity, solid content and lubricating/non-lubricating fluids.

- Centrifugal -For clean, low viscosity fluids such as water, thin fuels and water based chemicals, foods and petrochemicals

- Side Channel- For clean water and low viscosity chemicals even at high temperatures, and fluids with up to 50% gas content such as LPG and condensation

- Piston- For clean, low viscosity fluids such as water, thin fuels, oils and water based chemicals and petrochemicals

- Screw- For clean fuels, oils and other lubricating fluids thanks to its ability to handle fluctuations in viscosity caused by temperature changes

- Gear- For clean fuels, oils and other lubricating fluids thanks to its ability to handle fluctuations in viscosity caused by temperature changes

- Vane- For clean fuels and other low to medium viscosity liquids, even at high temperatures, including alcohols, chemicals and oils

- Progressive Cavity- For highly viscous fluids, sludges and slurries, dirty water, waste oils, solid-laden liquids, foods, gas-liquid mixtures and shear sensitive fluids

- Peristaltic- For almost any fluid including aggressive chemicals, viscous liquids, foods and high solid slurries thanks to its inner tube being the only wetted part

- AOD- For almost any fluid including aggressive chemicals, viscous liquids, foods and high solid slurries as the diaphragm can be constructed of many materials

- Flexible Impeller- For almost any fluid including water, chemicals, oils, liquids with high solid content, foods and shear sensitive fluids thanks to the differing impellers materials