| Flow Rate | Up to 3m³/hr |

| Max Head (pressure) | Up to 24 bar |

| Max Temperature | 140°C |

| Maximum Viscosity | 1,000,000CP |

| Sizes Available | From 010-2 to 022-1 |

| Flow Rate | Up to 3m³/hr |

| Max Head (pressure) | Up to 24 bar |

| Max Temperature | 140°C |

| Maximum Viscosity | 1,000,000CP |

| Sizes Available | From 010-2 to 022-1 |

The Nova Rotors MN series areprogressive cavity pumpscommonly used as dosing pumps thanks to their constant and precise flow output. The design of this progressing cavity allows for the pumping of dense and viscous fluids containing solids at very small and precise flow rates. The MN series of helical rotor pump is also excellent at handling shear sensitive fluids; this is due to the fact the pump generates low pulsations so there is less agitation caused to the pumped medium. Frequent applications of this Nova Rotor mono pump include oily sludge transfer, bilge water transfer, sewage transfer, bio-waste and alcohol transfer.

This dosing pump is also available as a food grade progressing cavity pump constructed from polished stainless steel 316 and a food grade stator. Typical food transfer pump applications include fruit juice pulp, beer, fruit paste, grapes, grape paste, wine and edible oils.

Read our progressing cavity pumpguidefor more detail on how this pump operates and its popular uses.

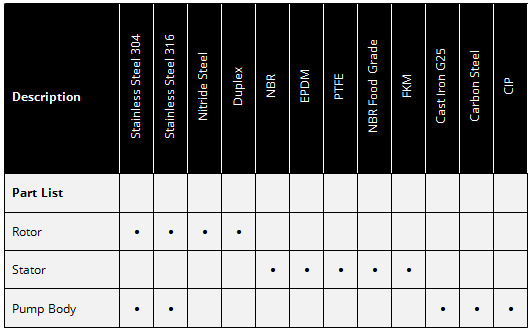

The Nova Rotors MN progressive cavity pumps are available with the following material options:

A new customer approached us that needed a pump for an abrasive slurry of fuel oil and coal dust. The pump needed a low flow rate and the ability to handle abrasive coal dust, whilst also needing to be controlled by a variable speed drive for testing purposes. We supplied a progressing cavity pump as its properties and capabilities were the best match for the requirements.

Castle Pumps pride themselves on being able to specify and design solutions to meet individual customer needs. This case study demonstrates this, where in order to meet the adjustable flow rate requirements of dripping lubricants onto wood fibres, Castle Pumps ensured that a motor variator was added to the unit to control the speed of the pump.

Castle Pumps are fully accredited to enable you to buy with confidence. Our accreditation includes:![]()